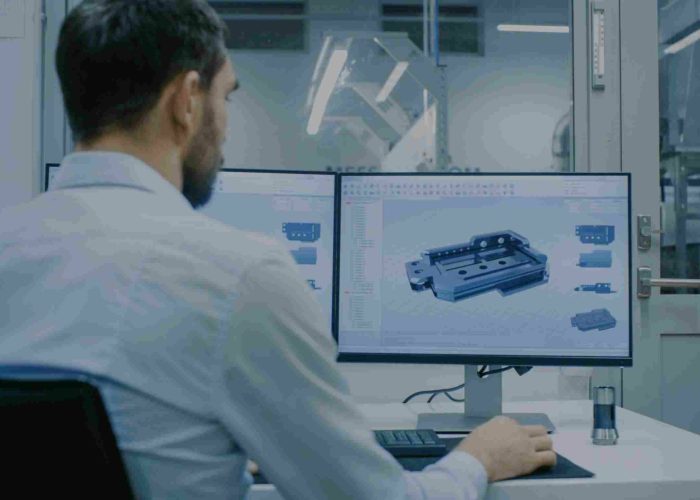

Capabilities

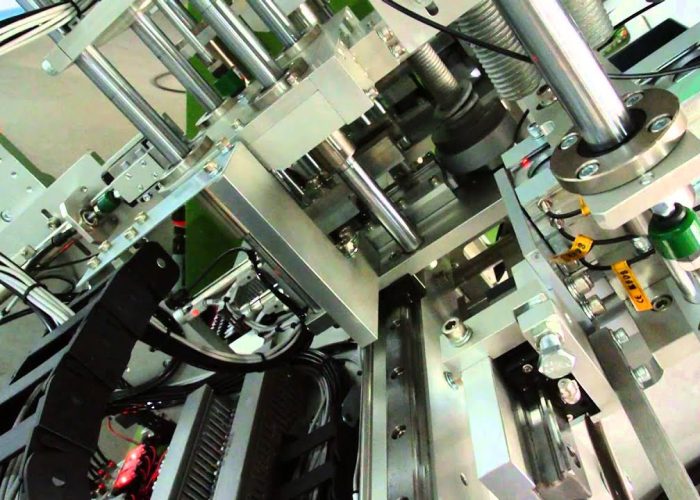

Custom Design & Solution

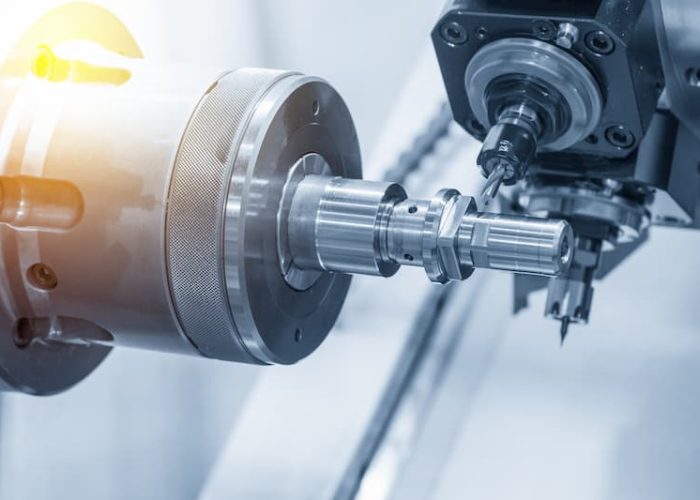

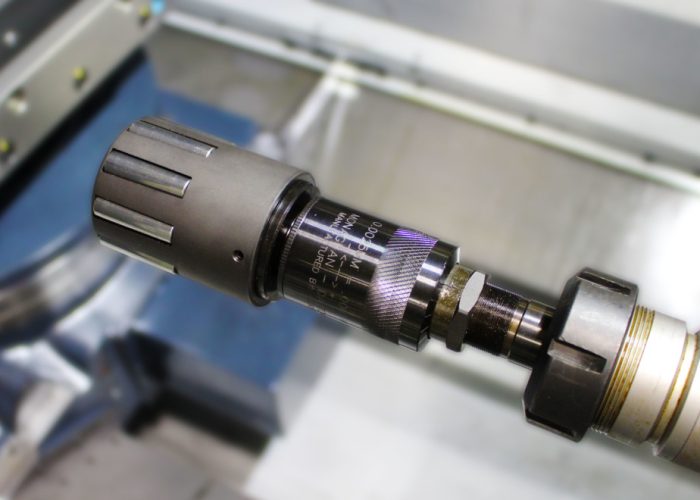

CNC Turning

Grinding

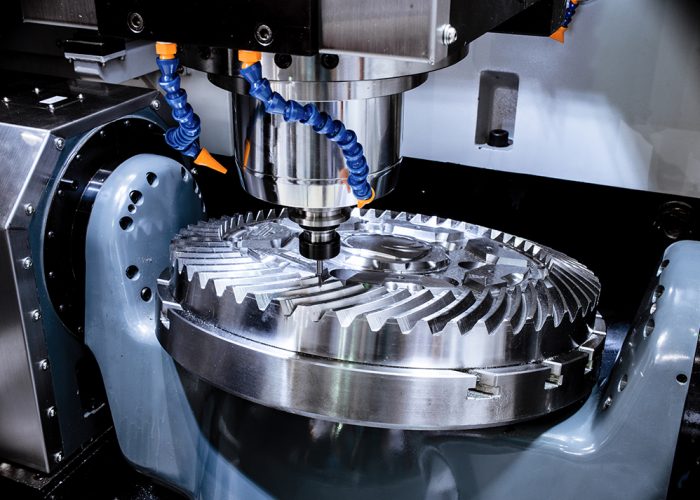

CNC Milling

Broaching

Polygon

Honing

Burnishing

Welding

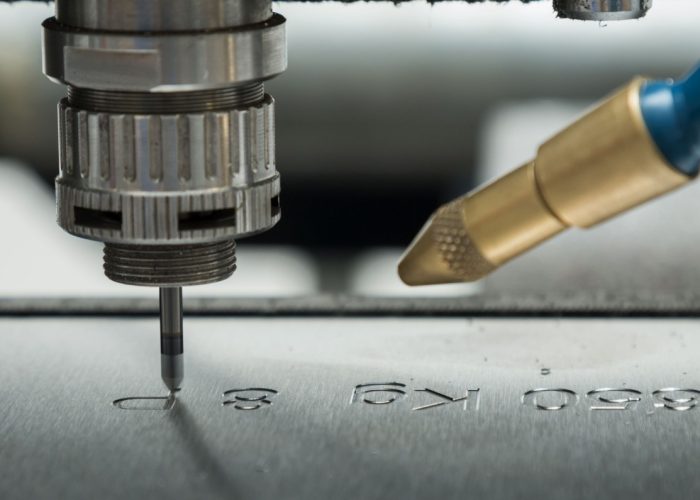

Engraving

Laser Marking

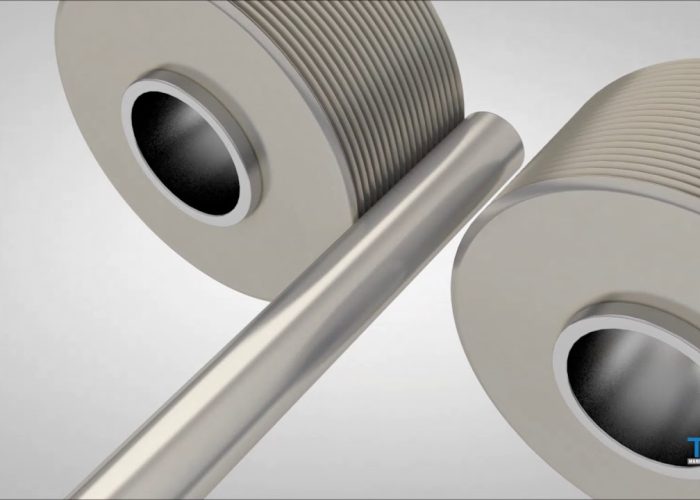

Thread Rolling

Internal Burnishing And Grinding

Processed Raw Materials & Treatments

Assembly

Procesed Raw Materials & Treatments

Bar Stock

- Round up-to Dia 350mm

- Hexagonal up-to 110mm

Forgings

- Open Die-up-to 180 Kgs

- Closed Die-up-to 80 Kgs

- Ring Rolling – upto 150 Kgs & Diameter 1000mm

Castings

- Process Investment

- castings, Sand,

- Shell Molded.

Material Grades

Low & Medium carbon steel (AISI 1018, 1020, 1040, 1045 etc.) Alloy steel (AISI 4140, 4340, 8620, 1541, 8620, 20MnCr5 etc.) Stainless steel (AISI 304, 303, 316, 400 Series & 17-4 Ph etc.) Non Ferrous Metal (Alluminium, Brass, Alluminium Bronze & Gun metal, etc.)

Raw Material Certification

PED 97/23/EC and AD2000or equivalent certifications from the source, wherever applicable. We work not only to Produce but to give value to time.

Value-Added Subcontracting Services

- Gold Plating

- Nickel Plating

- Zinc Plating

- Cadmium Plating

- Chrome Plating

- Hard Chrome Plating

- Silver Plating

- Tin Plating

- Copper Plating

- Power Coating

- CED Coating

- PTFE Coating

- Case Hardening

- Hardening & Tempering

- Induction Hardening

- Salt Bath Annealing

- Solution Annealing

- Through Hardening

- Anodizing

- Electropolishing

- Hard Anodizing

- Pickling

- Nitriding

- Nitro-Carburizing

- Quench polish Quench

- Buffing

- Phosphating

Are you looking for various Components Solution with utmost Precision?